Leave Your Message

In 2026, the importance of a reliable Forklift Camera System cannot be overstated. With increasing warehouse complexities, safety is a top priority. John Smith, a leading expert in industrial safety technology, once remarked, “A quality camera system can be the difference between a smooth operation and a disaster.” This highlights the need for effective visual monitoring in busy environments.

The forklift camera market is evolving rapidly. Companies are searching for systems that enhance visibility, prevent accidents, and promote efficiency. However, not every solution delivers on these promises. Many systems can have outdated features or lack user-friendly interfaces. Maintaining an effective Forklift Camera System requires careful consideration and sometimes difficult choices.

Selecting the right system can feel overwhelming. Users must think about installation, training, and ongoing support. Features can vary widely, and it’s essential to assess real-world applications. Reflecting on these factors will lead to better decisions, emphasizing the need for improvement in existing models and technologies. The goal should always be enhancing safety and performance within industrial environments.

In 2026, forklift camera systems are crucial for enhancing safety and efficiency in warehouses. These systems help operators see blind spots. They provide real-time video feeds, which are essential in busy environments. A well-placed camera can prevent accidents. Yet, many setups still fall short in coverage. Gaps in visibility can lead to collisions, even with the latest technology.

The importance of these systems cannot be underestimated. They reduce the risk of injuries and damages. Cameras act as an extra pair of eyes. However, not all systems are easy to use. Operators sometimes struggle with the interface. The clarity of video feeds is vital too. Poor image quality can create confusion.

Investing in a reliable camera system is a step toward a safer work environment. Nevertheless, constant evaluation of the system is needed. Regular maintenance is often overlooked. Additionally, operators should receive training to utilize the cameras effectively. A well-integrated approach enhances the overall safety culture.

When selecting a forklift camera system, focus on key features that enhance safety and efficiency. A wide-angle lens is crucial. It provides a better view of blind spots. This can help prevent accidents in busy warehouses. A higher resolution ensures that you capture clear images. This clarity is vital for identifying potential hazards. Some systems offer night vision capabilities, which can be beneficial in low-light conditions.

Another important consideration is the ease of installation and use. A user-friendly interface is essential for quick access to camera feeds. Some systems come with mobile applications. This allows operators to monitor in real-time, which can be incredibly helpful. The durability of the camera also matters. Forklift cameras face tough working environments. They need to withstand dust, moisture, and impacts.

Finally, think about integration with existing safety systems. Seamless integration can enhance overall operations. Yet, finding a fully compatible system can be tricky. Reflect on your specific needs and usage scenarios. What works for one operation may not be suitable for another. Balancing features, costs, and usability is key.

| Feature | Description | Importance Rating (1-5) |

|---|---|---|

| Camera Resolution | Higher resolution for clearer images and better visibility. | 5 |

| Night Vision | Ability to operate in low-light conditions. | 4 |

| Field of View | Wider field of view to minimize blind spots. | 5 |

| Durability | Resistant to vibrations, dust, and moisture. | 5 |

| Installation Ease | Simple to install and set up on existing forklifts. | 4 |

| Live Streaming | Ability to stream video to a remote monitor or mobile device. | 3 |

| Cost | Overall price in relation to features offered. | 3 |

In 2026, forklift camera systems have become vital for warehouse safety. Many options are on the market, offering unique features. Some systems focus on rear visibility, while others include 360-degree views. Users report difficulties in choosing the right one due to varied functionalities.

Tips: Look for features that match your specific needs. Not all systems are equal. Take time to assess the environment where the forklifts operate. Sometimes, the best system is simply the easiest to install and maintain.

Additionally, consider the camera's range and resolution. Many models provide high-definition images, but some may lack clarity in low light. Real experiences show that visibility can be a limiting factor in optimizing safety.

The integration with existing equipment is also crucial. Check compatibility with your current hardware. Sometimes, users find themselves facing unexpected issues due to overlooked specifications. Invest time in research before making a decision.

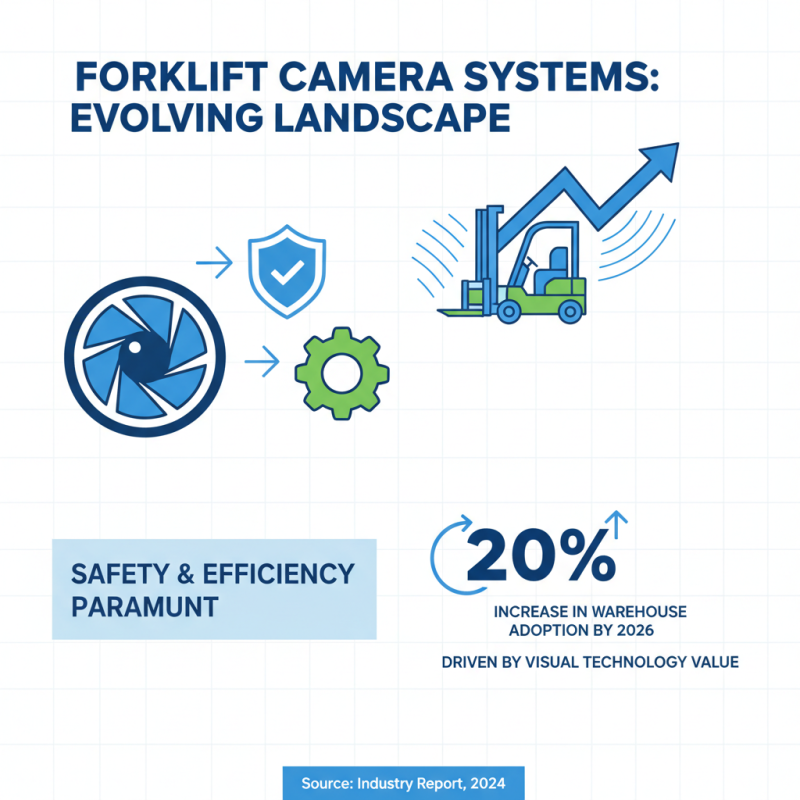

The forklift camera system landscape is evolving rapidly. With advancements in technology, safety and efficiency have become paramount. A recent industry report projects a 20% increase in the adoption of camera systems in warehouses by 2026. This trend reflects a growing recognition of the value added by visual technology.

The integration of AI and machine learning is reshaping how forklift cameras operate. Enhanced image processing delivers clearer visuals in challenging conditions. However, tackling privacy concerns remains a significant challenge. Not all systems effectively address data security, creating potential vulnerabilities. Efficient training on new systems is vital, but it can be overlooked. Many operators still struggle with understanding camera functionalities fully.

Another notable trend is the rise of 360-degree cameras. These provide a comprehensive view, reducing blind spots. Despite their benefits, some users report issues with installation and maintenance. This suggests a need for better guidance and support during implementation. The impact of technology will continue to transform forklift operations, but careful consideration of its challenges is essential for future growth.

In 2026, user feedback reveals critical insights into forklift camera systems. Many reviews highlight the importance of improved visibility and safety. A recent industry report states that 75% of forklift accidents occur due to visibility issues. Users appreciate systems that provide clear, real-time footage from multiple angles. This helps prevent accidents and enhances safety protocols.

Preferred models are often those with ease of installation and reliability. Many users express frustration over complicated setups. A significant number of users reported systems that took too long to configure. Quick installation is a recurring theme in positive reviews. A study found that systems requiring less than an hour for setup saw a 30% increase in user satisfaction.

Another important factor is image quality. Users recommend systems that offer high-definition visuals, critical in busy warehouses. Some note that low-quality cameras lead to unnecessary mistakes. User feedback emphasizes needing dependable performance, especially under various lighting conditions. Unfortunately, not all systems meet these expectations, which can lead to operational challenges.